injection molding

Precision Group excels in molding innovation, showcasing unmatched expertise that defines industry standards for precision, quality, and cutting-edge manufacturing.

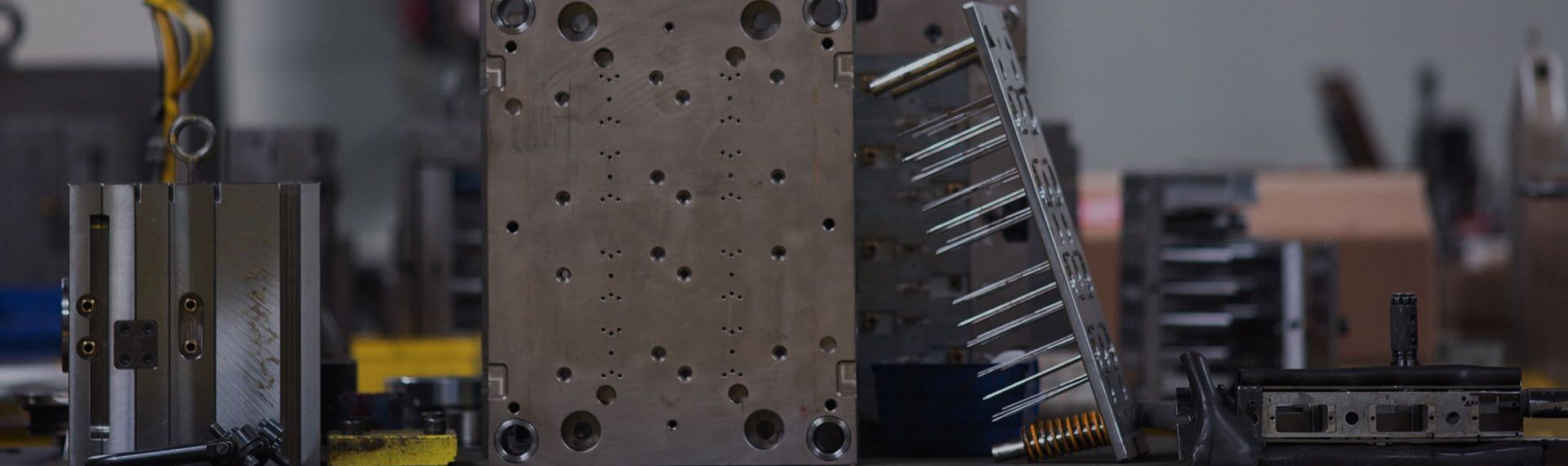

MOLDING EXCELLENCE

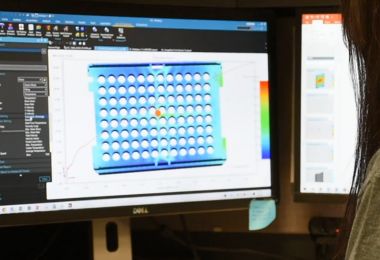

Discover the epitome of molding excellence with Precision Group’s Molding Services, where versatility meets precision across a full range of molding machines. Our extensive capabilities span from 55 to 610 tons, featuring state-of-the-art presses that are not only powerful but also fully electric and automated. Whether you need high-volume production or intricate molding for specialized components, our Molding Services are tailored to deliver exceptional quality and efficiency.

Our molding machines, ranging from 55 to 610 tons, leverage cutting-edge automation technology, ensuring not only precision but also enhanced productivity. Whether it’s injection molding or over-molding, our team of experienced technicians and engineers is equipped to handle projects of varying complexities, delivering molded components that meet the highest standards.

Choose Precision Group as your preferred partner for molding services, and benefit from our commitment to quality, speed, and innovation. Our full range of molding machines, coupled with advanced automation, allows us to efficiently produce components with intricate details while maintaining consistency and repeatability. Elevate your molding projects with Precision Group, where precision, technology, and a diverse range of capabilities converge to meet the unique demands of your industry.

COMMITMENTED TO EXCELLENCE

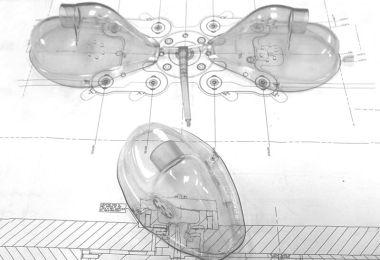

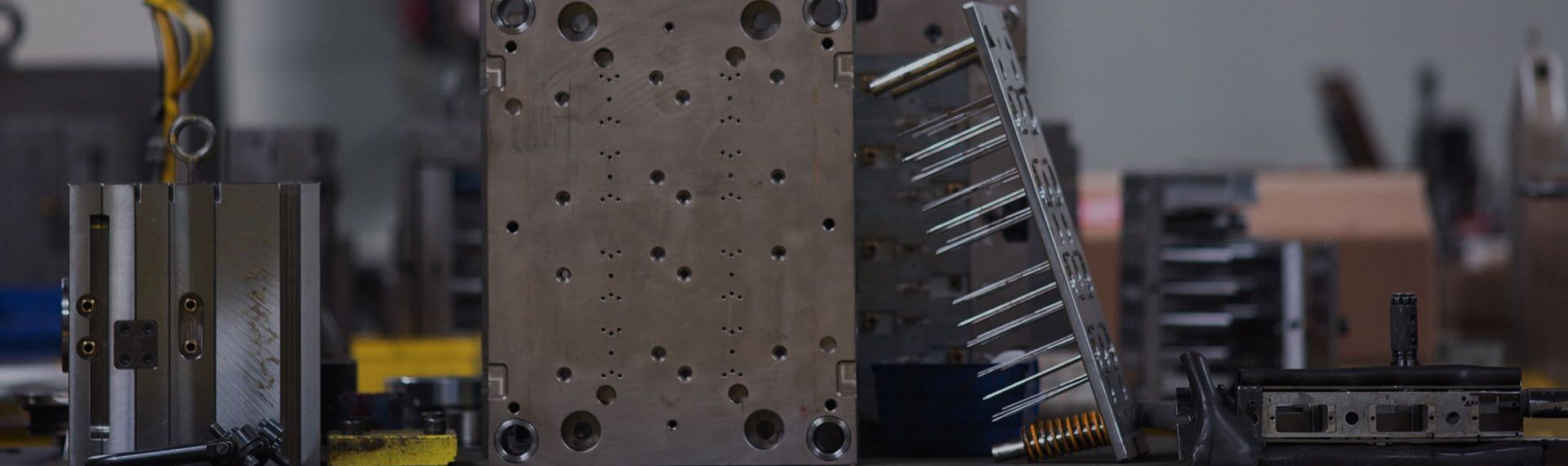

Your trusted destination for comprehensive Contract Manufacturing services. Our integrated solutions cover the entire spectrum of manufacturing needs, from precision molding and tooling to pad printing and light assembly. We are committed to excellence and offer a one-stop-shop experience for businesses seeking a reliable partner for their diverse manufacturing requirements.

Precision Group takes pride in its advanced molding capabilities, equipped with a full range of machines spanning from 55 to 610 tons. Our expertise extends to tooling services, ensuring that every mold is crafted with precision to meet your specific project requirements. Beyond molding, our capabilities include pad printing, adding a finishing touch to your products with intricate designs and branding. Light assembly services further complement our offerings, providing a seamless transition from production to the final product.

Choose Precision Group for your Contract Manufacturing needs and experience the synergy of precision and efficiency. Our team of skilled professionals is dedicated to delivering high-quality products, meeting tight deadlines, and ensuring cost-effective solutions for your projects. Whether you require molding, tooling, pad printing, or light assembly, Precision Group stands ready to be your reliable partner, streamlining your manufacturing processes and bringing your vision to fruition with precision and expertise.

PRISTINE PLUS PRECISION

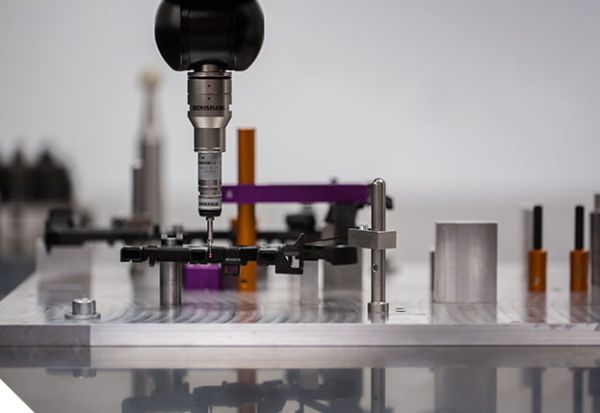

Step into the pristine world of precision manufacturing with Precision Group’s Clean Room Class 8 ISO-Certified services. Our state-of-the-art Clean Room facility is equipped to handle a spectrum of advanced processes, ensuring the utmost precision and cleanliness at every step of the manufacturing journey. From molding to vacuum-sealed packaging, our Clean Room services are designed to meet the most stringent requirements of industries such as medical, electronics, and aerospace.

Precision Group’s Clean Room Class 8 ISO Certified Molding takes precision to the next level, maintaining an environment that meets the highest cleanliness standards. Our expertise extends to heat staking, UV light curing, and vacuum testing, ensuring that your products are not only meticulously manufactured but also adhere to the strictest quality standards. The Clean Room environment is further enhanced with automated adhesive dispensing solutions, employing cutting-edge Glue Bot technology for consistent and precise application.

Choose Precision Group for your Clean Room manufacturing needs, and benefit from a comprehensive suite of services. Our capabilities include ultrasonic welding, non-destructive leak testing, and secondary CNC machining operations to provide a full manufacturing solution. With vacuum-sealed packaging and adherence to industry standards such as FAI, IQOQPQ, and PPAP validations, Precision Group is your partner in achieving manufacturing excellence in a controlled and clean environment. Experience the difference between precision and cleanliness with our Clean Room Class 8 ISO-Certified.

Visit our specialized landing page to know our full capabilities and certifications. CleanRoomManufacturing.com